Research Facilities

Unmanned Aerial Vehicles Lab

The UAV Lab under the Aerospace Engineering division has drone fabrication and testing facilities, along with advanced simulation systems. This comprehensive setup enables the design, construction, and rigorous evaluation of UAVs. The lab is equipped with various tools for prototype development and performance analysis. Furthermore, it benefits from the expertise of two faculty members who hold DGCA-issued drone pilot licenses for the small category, ensuring adherence to regulatory standards and enhanced practical training for students. The lab serves as a hub for innovation, research, and hands-on learning in the rapidly evolving field of unmanned aerial vehicles.

Small Category Type Certified Drone

DGCA-approved Type Certified Garuda Kisan Drone

The Garuda Kisan Drone is an advanced agricultural UAV designed to aid farmers in modernizing their crop management techniques, this drone is equipped with precision technology for tasks such as aerial spraying, crop monitoring, and field mapping. The Garuda Kisan Drone features autonomous flight capabilities, allowing it to cover large areas efficiently and effectively. Its high-resolution cameras and sensors provide real-time data, enabling farmers to make informed decisions and optimize crop yields. This drone represents a significant step forward in smart agriculture, promoting sustainable farming practices and increasing productivity. Students gain hands-on experience in drone operation, UAV design, control systems, aerodynamics and data analysis. It serves as a hands-on educational tool for mastering drone technology and its applications in real-world scenarios.

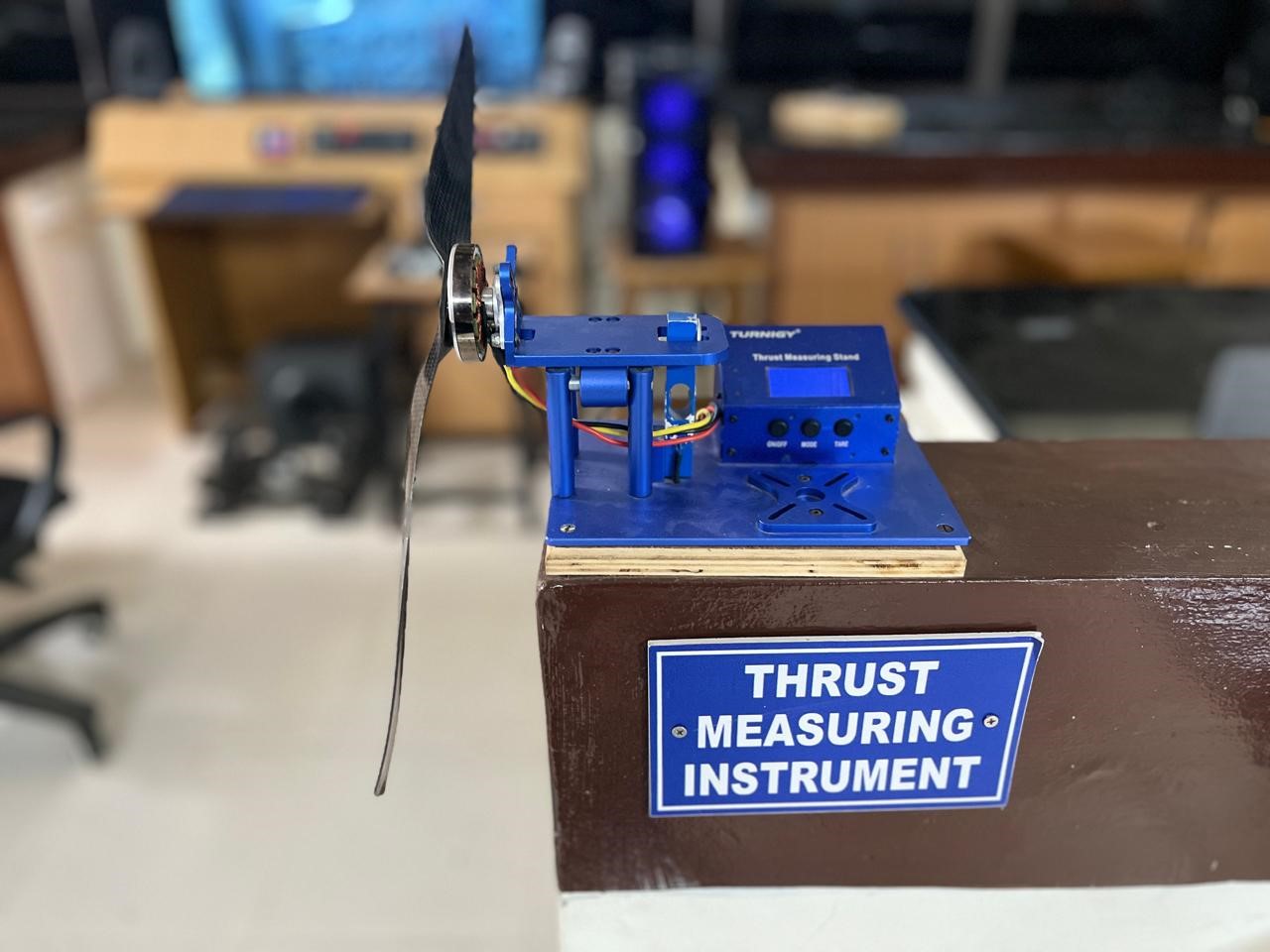

Thrust Measuring Instrument

Thrust Measuring Instrument

The Thrust Measuring Instrument in the drone lab is a crucial tool for aerospace engineering students, enabling precise measurement of UAV engine thrust. This device provides accurate data on the force generated by drone propulsion systems, essential for performance analysis and optimization. Students use it to understand the relationship between thrust, power, and efficiency in various flight conditions. The instrument supports hands-on experimentation and validation of theoretical models, enhancing learning in propulsion mechanics and aerodynamics. By integrating this tool into their studies, students gain practical insights into the design and testing of more efficient and powerful UAVs.

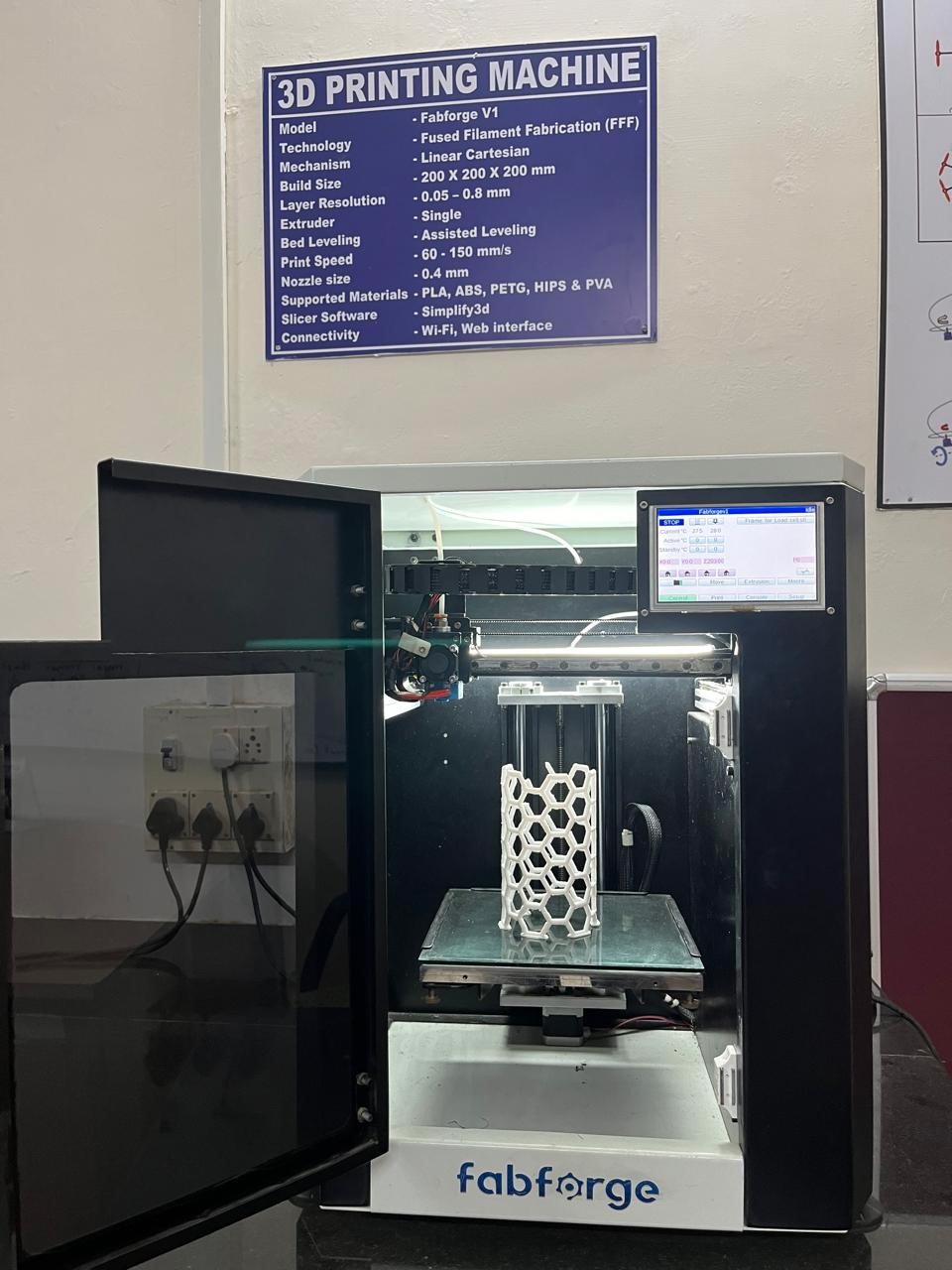

3D Printing Facility

3D Printer

The FabForge 3D Printing Facility in the drone lab offers aerospace engineering students access to advanced additive manufacturing technology. This facility enables the rapid prototyping and fabrication of intricate UAV components, allowing for innovative design and quick iteration. It supports the creation of custom parts, enhancing students' hands-on experience in UAV construction and material science. By utilizing this facility, students can experiment with different materials and geometries, fostering creativity and improving their engineering skills. This plays a pivotal role in bridging the gap between theoretical concepts and practical application in UAV design and development.

Composite Fabrication Facility

Composite Fabrication - Vacuum Resin Transfer Moulding facility

Composite materials are known for high strength to weight and high stiffness to weight ratios. Among various methods, the two ways of making the fibre reinforced polymer composite plates, such as the hand layup and the vacuum assisted resin infusion techniques are available in the laboratory.

Vacuum Resin Transfer moulding setup